Changeovers are one of the common causes of increases in downtime on a production line. You want your machines running as efficiently as possible, and that includes running for as much time as possible. Simply put: time consuming changeovers slow down your production.

We spoke with our container handling experts to gather 6 tips to make your changeovers more seamless.

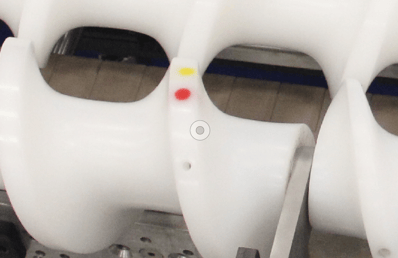

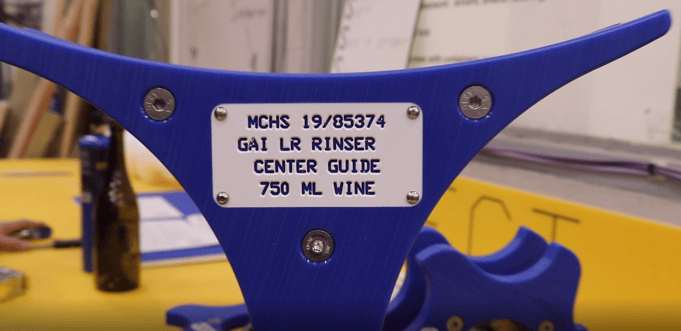

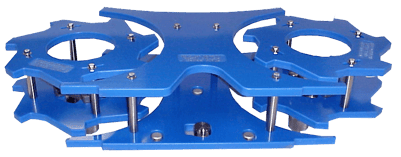

We recommend utilizing labels right on the stars, guides, and timing screws that will allow operators and maintenance personnel to quickly identify which parts go on the line for which container. At Morrison, we utilize color plugs or color coded change parts and screws in our manufacturing process that can coordinate with your product. For example, yellow may indicate the 28oz while blue may indicate the 178ml. We will also label this directly on our change parts. See the examples below.

You should also figure out a storage system that best fits your production line. This may be something like a parts cart, a movable cart designed to store and organize your container handling sets so everything stays where it can be found again. These carts keep timing screws, stars, and guides all in one location to make quickly locating the parts easier.

If your operators have steps to follow when it comes to changeovers, it gives them a guide to make sure they know what they’re doing, and you know your employees have the resources to do their job. This can be done in a number of ways. For example, a user manual that shows the changeover process or a video physically showing someone perform a changeover. Whatever the method may be, giving clear instructions on how changeovers should look can help make the process go smoother by providing the necessary training.

At Morrison, we include detailed manuals with our products that include maintenance and changeover procedures. If a new manual is ever needed for whatever reason, we can get you a replacement one right away.

Make sure the right people know when a changeover is happening and notify them with plenty of time. Another often overlooked step of the changeover process, but not surprisingly, people like to know what’s going on in their workplace. By giving your operators time to prepare for a changeover, it allows them to prep the tools they’ll need [unless they use tool-less Morrison parts], the amount of time they predict they’ll need, and other things often times only the operator or maintenance team thinks of. Clear communication across the board is key to having smooth changeovers.

Known as the Single-Minute Exchange of Die (SMED), this technique is a long used practice in the manufacturing field to reduce downtime. SMED refers to getting changeovers down to under 10 minutes by getting as many steps of a changeover done and out of the way, safely of course, while the machine still puts through product, in order to simplify the remaining steps needed to be done while the machine is stopped. The other steps in this article also contribute to making the changeover time goal of under 10 achievable.

Take out the variable of tools and you have one (or many) less things to worry about when it comes to changeovers. Lost tools, wrong sized tools, fiddling with tiny parts, all of these things can be a thing of the past when using tool-less quick change parts. Morrison quick change parts are made so a changeover can be as simple as lifting a pin and sliding a guide in or out of place, and often times these parts can be retrofitted to your existing machine. Learn more in this eBook.

Want to hear straight from our Aftermarket Service and Sales Manager on best practices for maintaining your Morrison equipment?

Join our monthly newsletter and have them delivered straight to your inbox.