It's that time again, time to replace your timing screws. Perhaps you're transitioning to a new container, or maybe the relentless wear and tear of production has finally caught up with your trusty plastic scrolls. With so many potential options to select from, how can you be certain you're choosing the right plastic for your needs?

The timing screw specialists at Morrison have developed a comprehensive check system to tackle this very issue. Based on many conditions, we will recommend specific plastics that hold up better in your plant environment. Learn more about the differences in plastics below.

First things first, what are your options?

In the world of manufacturing there are many options to choose from, but we have narrowed it down to the top 3 versatile plastics most commonly used on packaging lines.

- UHMW, or Ultra High Molecular Weight Polyethylene

- Delrin, also known as, Polyoxymethylene

- Nylon

UHMW

UHMW, with its exceptional durability, is renowned for its ability to withstand high impact. A staple on production lines, this plastic effortlessly handles high-speed applications. Its versatility extends to its color options as well, enabling you to color-code your screws to match container sizes. This not only streamlines changeovers but also enhances overall operational efficiency. Color options include:

- Black

- White

- Red

- Yellow

- Purple

- Pink

- Brown

- Grey

- and more!

Our UHMW solutions also offer an antistatic variant that's particularly beneficial to industries like petroleum. This feature effectively dissipates static charges, which are often generated when containers are operated at high speeds. By reducing the risk of sparks, this option can significantly enhance safety conditions in your operation.

Delrin

Delrin, a frequently used plastic in manufacturing, boasts remarkable wear resistance. Unlike UHWM, Delrin exhibits exceptional thermal stability, meaning it won't expand or swell due to the temperature or humidity of your operations. This material is ideal for situations requiring precise handling and within the screw. As a result, it finds extensive application in the medical and pharmaceutical industries.

Nylon

Last but not least, Nylon is commonly used in operations involving glass bottles and containers. Lightweight and cost-effective, this plastic offers a unique characteristic that sets it apart from the plastics mentioned earlier. In the event of a glass bottle breaking, Nylon plastic will break away with the container, preventing splintering or shattering that could cause further issues downstream and still allow the screw to perform correctly.

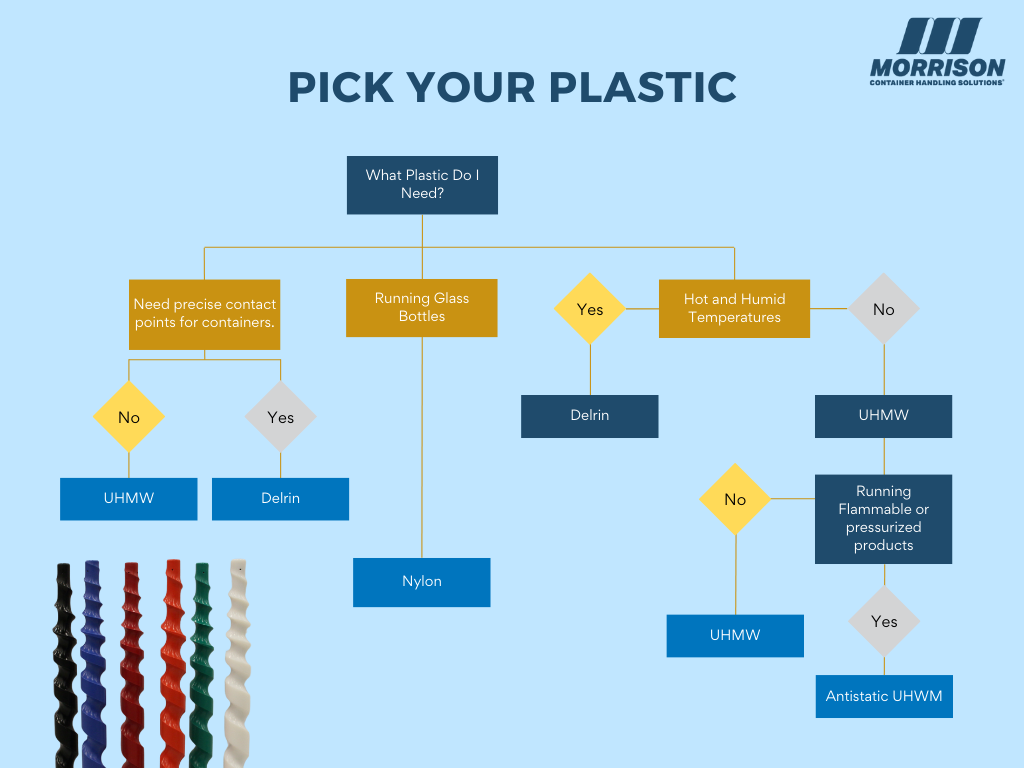

Now that we have an overview for each plastic and their unique properties, it’s time to decide which plastic is right for you. Below is a chart that can help walk you through this process.

As you make your decision, the timing screw experts are always here to help guide you through this process. For more information fill out the form here.