Partnership takes on a special meaning for Morrison Container Handling Solutions and ProSys Servo Filling Systems.

Since 2017, Morrison and ProSys worked together to provide cartridge filling systems for ProSys’ customers. A testament to what can stem from robust discussions at Pack Expo trade shows, Morrison provided container handling for ProSys systems allowing ProSys to better serve their customers and set themselves apart from the competition. Morrison partners with OEMs on their projects allowing them to elevate their production.

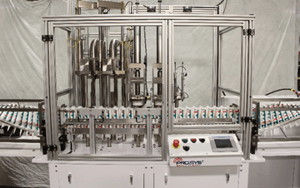

Each system features an inline filling system with container handling provided by Morrison and filling by ProSys. As the Morrison screws and machine design accurately position each tube within 1/16th of an inch, ProSys maintains a fill accuracy of +/- 1 percent. This dedication to accuracy on the systems leaves customers with a powerful unit capable of filling up to 120 containers per minute.

“The Morrison indexing screw system applied in these machines allows ProSys to better achieve their accuracy goal and deliver precise, efficient machines that give ROI quickly,” says Ryan Finke, Morrison’s Vice President of Engineering. “It makes sense for Morrison, since we have the same focus in our engineering: delivering quality solutions that will help our customers save and produce.”

The project came to fruition when ProSys saw Morrison’s capabilities at Pack Expo International and wanted to improve the container handling aspects of their cartridge filling product lines. Adam Thomas, ProSys’ Project Manager, said Morrison was able to utilize their container handling expertise to provide a new way for ProSys to handle the cartridges. Taking a horizonal infeed to a vertical filling approach, allows ProSys to deliver an improved cartridge handling solution for customers in the industrial sealant, adhesive and grease markets.

“With the way we worked together to lay out these systems, we’re able to provide a more compact and versatile system that allows our rates to be faster and integrate into a variety of full production lines,” Thomas said. “This design with Morrison has resulted in more orders and opportunities to work on larger lines.”

The vertical fills allow ProSys to handle a wider variety of liquids in these machines compared to competitors, from very thin to very thick viscosities. In this indexing system, Morrison helps Prosys integrate printers and check weighers when needed as well, helping customers achieve better fill accuracies that equate to savings and less overall product waste.

“Partnering with another company isn’t always easy, but with ProSys we have found a partner who is committed to robust communication and customer support,” says Morrison’s CEO Nancy Wilson. “It has resulted in growth for both companies. By giving and receiving feedback, our engineers learn how working together with OEMs allows us to provide more robust solutions that meet more customer needs, which is why we design custom equipment in the first place. It’s Support Built In at its finest.”

Throughout the last five years, more than 13 machines have been placed in production, with one of those earliest designs being upgraded at Morrison this year to the latest mutually developed innovations.

“Working with Morrison makes the project easy,” Thomas said. “They’re responsive and focused on giving us a solid solution. There’s a great back and forth that happens in the design process that allows us to engineer better products together.”

Thank you to ProSys Servo Filling Systems for providing the photos in this post.

ABOUT PROSYS SERVO FILLING SYSTEMS:

ProSys is a premier manufacturer of high-performance SERVO filling machinery for filling cartridges, squeeze tube, unit dose tubes, single & dual barrel syringes, airless pumps and rigid containers for the Cosmetic, Pharmaceutical, Food, Chemical, Adhesive, Sealant and Grease Industries. Driven by a passion for innovation and excellence in design, manufacturing and after sales service, ProSys delivers leading edge filling machinery and technologically advanced solutions for tube filling, cartridge filling, syringe filling and airless pump applications. ProSys offers custom designs and turnkey systems for unique containers and new packaging concepts. Their advanced control systems feature servo drives, hazardous area controls and are ethernet ready for direct plant connections.